Innovative Calender Machines

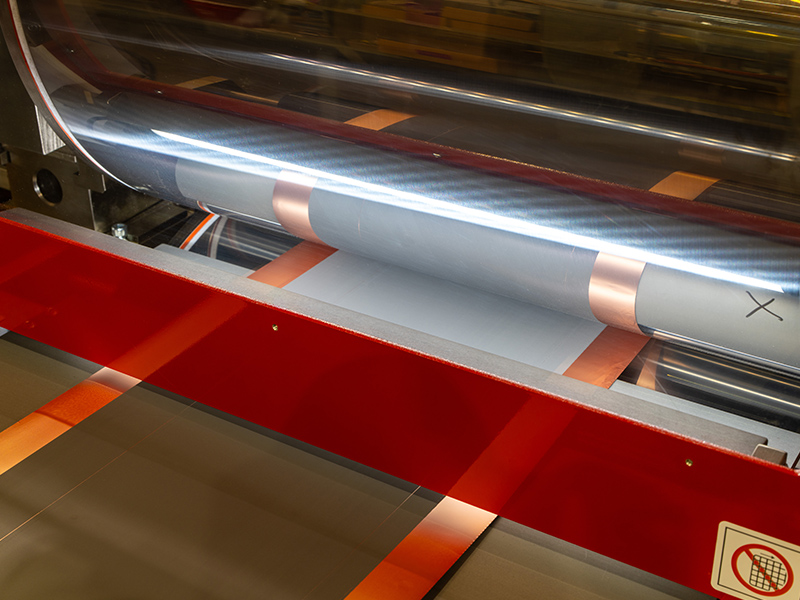

Calender machines are one of our specialties. These robust machines combine extremely high compression capability with precision. We are one of the leading machine manufacturers in the demanding high-energy/power battery industry for a reason: Our machines perform.

Our machines are also used for plastics processing, PTFE, filtration media, and paper processing. Typical calender machine functions are material compression and surface finish.

Options we offer include uniformly heated rolls, non-contact thickness gauges, automatic gap control, automatic pressure adjustment, beta gauges, turret unwinds/rewinds with auto splice, pre-heat, and more.

We offer a standalone or can integrate with an existing production line. Sizes range from small tabletop to high-speed, full-automation production. Multi-roll configurations are also available. Experienced engineers can custom-design your machine.

- Designed for metering, thermobonding, laminating and smoothing.

- Covers paper, film, foil, non-wovens, powder and battery

- Roll configurations: crowned, thermal shell, heated/cooled

- Tight Tolerance (micron level)

- Deflection controlled via crowned roll, skewing and roll bending

- Integration of third party metrology Extreme surface hardness, toughness, surface finish designed for the most demanding applications