Innovative Coating Machines

Quality coating requires experience, process knowledge, and precise machine design. Since the mid-1950s, Innovative Machine Corporation has been designing and building high-performance coating lines for demanding roll-to-roll applications. Our roots in magnetic tape coating established a strong foundation in precision fluid delivery, web handling, and thickness control—expertise that continues to drive our designs today.

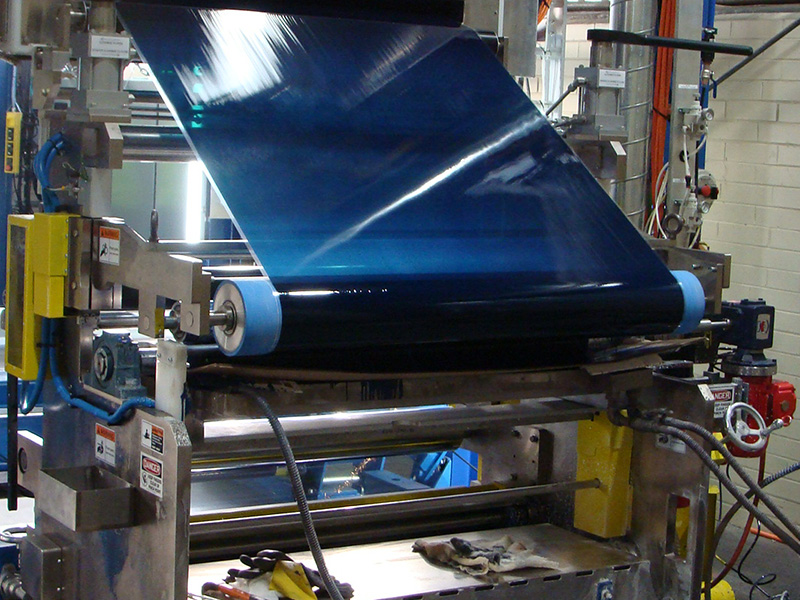

Building on that experience, IMC coating systems are widely used in advanced applications including battery electrodes, printed electronics, display films, filtration membranes, and other engineered materials. These processes demand tight coating tolerances, uniformity across the web, and repeatable performance under continuous production conditions. Our machines are engineered to meet those requirements with stability, accuracy, and long-term reliability.

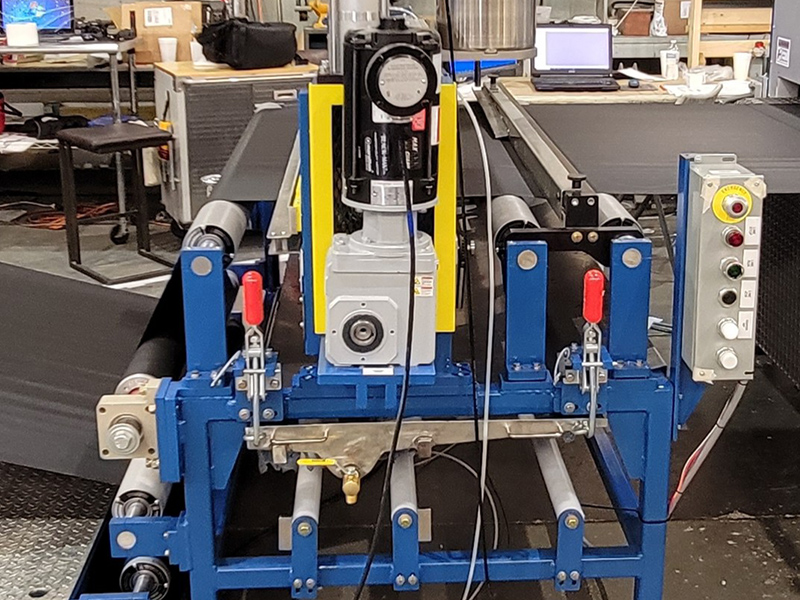

While we offer proven standard coating platforms, the majority of our projects are custom-engineered to match a customer’s specific process and product requirements. Coating lines can be supplied as standalone systems or fully integrated manufacturing lines incorporating additional processes such as lamination, slitting, embossing, calendering, inspection, drying, cutting, or stacking. IMC engineers work closely with customers to develop complete solutions—from raw material unwind through finished product handling.

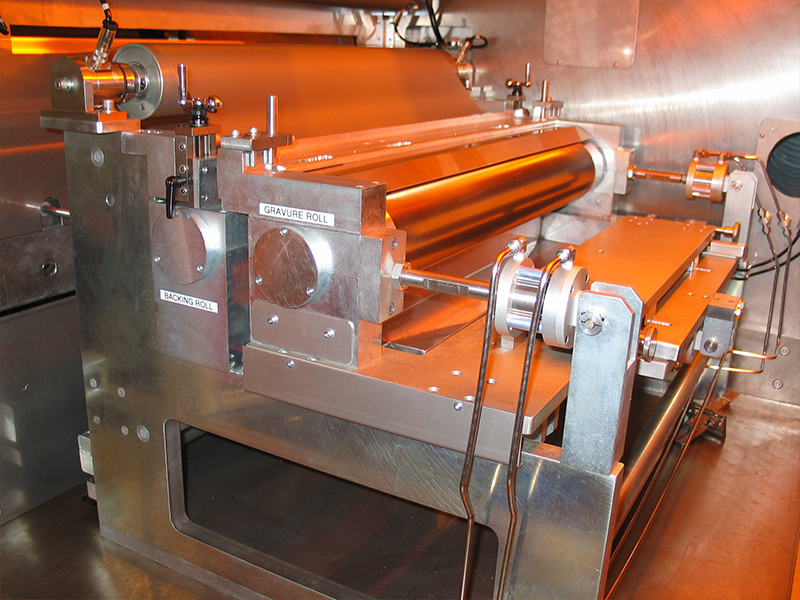

IMC supports a wide range of coating technologies, including slot die, reverse roll, knife-over-roll, and gravure coating. Systems are designed to handle aqueous, solvent-based, and hot-melt formulations, with careful consideration given to fluid rheology, drying requirements, and process control. Each coating machine is engineered to deliver consistent coating quality while maintaining flexibility for future process adjustments.

- Precision Slot Die, Gravure, Knife Over Roll, Reverse Roll, Comma, Saturation, Hot Melt

- Explosion Proof Option - Class 1, Group D

- Integrated Quality Monitoring & Process Control Systems

- Idler Support, Air Float, IR, Convection, UV

- Vertical or Horizontal Layout

- Continuous Production with Auto-Cutover Winders

- Precision flow control and metering

- Cleanroom and dry room ready

- Lab, pilot and production scale platforms