Web Drying Ovens

Efficient drying and precise curing are critical factors that directly impact product quality, line speed, and overall process stability in web converting operations. Innovative Machine Corporation designs and manufactures custom drying and curing systems engineered to deliver uniform thermal performance while protecting sensitive substrates and coatings.

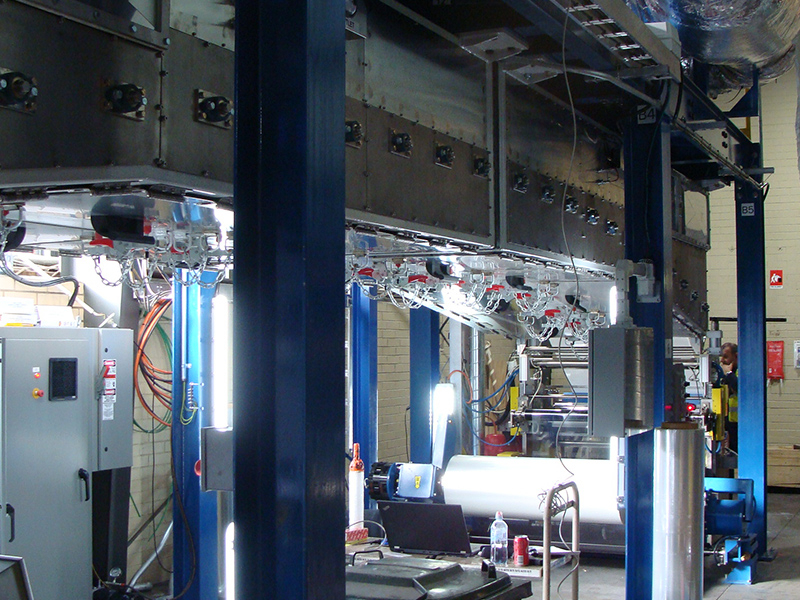

IMC drying solutions include air flotation dryers, counter-flow and through-air convection systems, infrared (IR) dryers, and UV curing technologies. Each system is engineered to match the specific coating chemistry, solvent load, web material, and production requirements of the application. Careful attention is given to airflow distribution, heat transfer, and exhaust management to ensure consistent drying or curing across the full web width.

Our dryers are designed with precise zone control to allow gradual moisture or solvent removal, minimizing defects such as blistering, cracking, curl, or uneven coating properties. Thermal uniformity and controlled residence time enable higher line speeds while maintaining coating integrity and repeatable results.

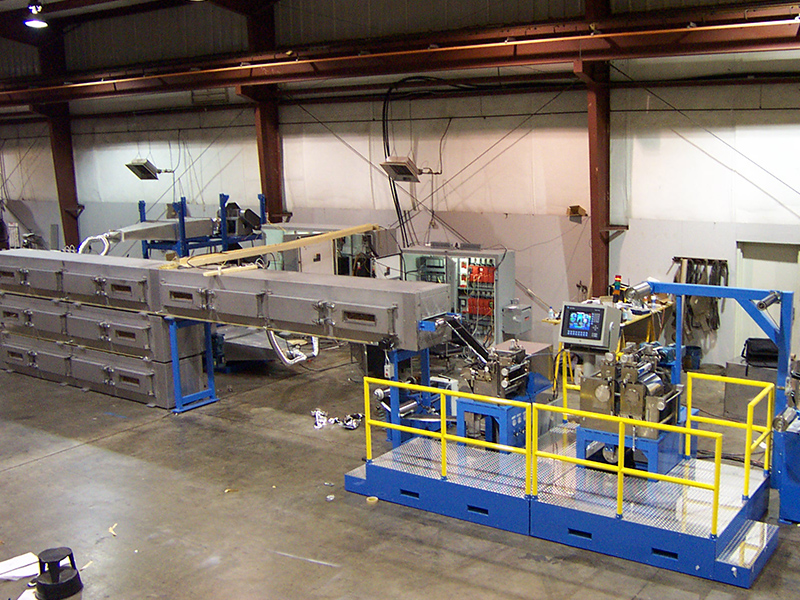

Dryer configurations are customized to fit both process requirements and available floor space. Web paths may be straight, arched, stacked, or serpentine, and systems can be supplied as standalone units or fully integrated into complete coating, laminating, or converting lines. IMC engineers work closely with customers to develop drying solutions that maximize performance, efficiency, and long-term reliability.

- Designed for Non-Explosive or Explosive (Class 1, Group D)

- Uniform airflow distribution for consistent web drying

- Convection, Infrared, hybrid, Radiant UV and IR systems

- Electric or Gas Options

- Energy efficient designs to lower operating costs

- Integration with Exhaust Management Systems Including Heat Exchange, Recirculation, Solvent Recovery, Oxidizer

- Custom chamber configuraion (horizontal, vertical, arched)

- Designed for integration with coating, laminating and other converting lines